Cosmetic process water

- Location

- Bekasi, Indonesia

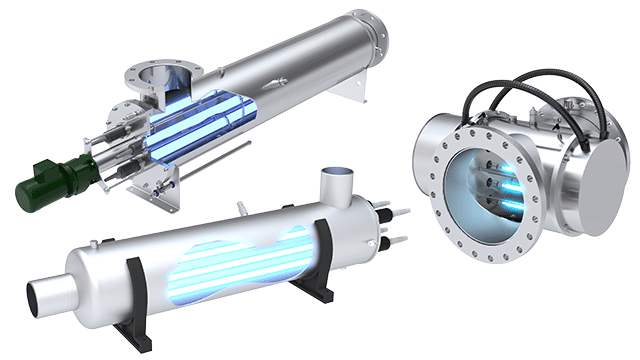

- Technology

- Ultraviolet

- Equipment

- UV DW

Water is widely used in the industry and must be treated and disinfected to protect processes, people and the environment. Global pressure to reduce the environmental footprint and the need to produce more sustainably, as well as increasing operating costs and changing regulatory requirements are constant concerns for industrialists. Industrial water treatment processes are specific to each application and include a wide variety of treatment steps to ensure the required quality of the water, at all stages.

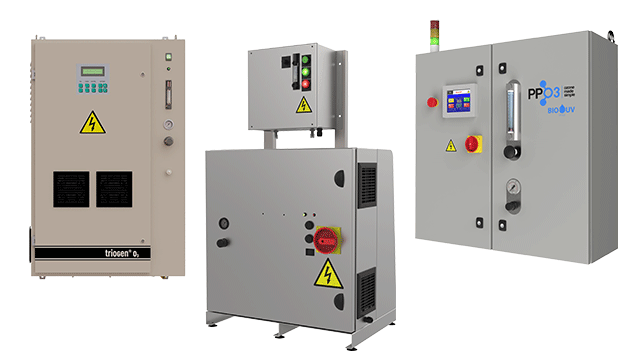

BIO-UV Group was founded with the aim of improving and securing water quality by providing professionals with cutting-edge technologies without the addition of chemicals.

Process water treatment is essential to maintain optimal production in various industries. The goal is to meet high production standards while optimizing energy costs and minimizing waste. The complex challenges of the sector require technologies that are simple to use, proven and efficient.

In agri-food, for example, large quantities of water are used daily to transform raw ingredients into marketable products. UV and ozone help to secure water quality, limit bacteria and viruses, and ensure stable key parameters. BIO-UV Group collaborates with its partners to contribute to food safety while protecting the natural environment.

To protect natural ecosystems (rivers, lakes, beaches, coastal areas), regulations limit industrial discharges. Contamination can include various pollutants and pathogens. Wastewater treatment removes these contaminants, reducing environmental impact and allowing water to be reused for agriculture, irrigation or cleaning.

UV and ozone systems target unwanted micro-organisms and pollutants, with adaptability and modularity according to the specific needs of the site.

Legionella bacteria develops in cooling towers and hot water systems between 20 °C and 45 °C. Legionellosis, a potentially life-threatening pneumonia, contracts by inhalation of contaminated droplets.

BIO-UV Group offers UV solutions to create a microbiological barrier, limiting the proliferation of legionella and ensuring quality hot and cold water.

The CIP disinfects equipment, pipes, filters and containers without dismantling, with little or no manual intervention. Improper cleaning can harm health, the economy and the environment. UV and ozone systems are widely used in food, pharmacy and beverage industries to ensure hygiene and regulatory compliance while removing organic and inorganic compounds without harmful chemicals.

Water sources are often disinfected with chlorine or ozone, residual which can harm industrial processes. UV effectively neutralize these oxidizing agents while ensuring complementary disinfection.

Ultra-pure water meets very strict specifications on microorganisms, organic and inorganic compounds, dissolved solids and gases. It is essential for microelectronics, energy, optics, cosmetics and pharmacy. UV and ozone maintain sterility and remove residues, ensuring water quality. The UV also guarantees the destruction of residual ozone incompatible with certain precision processes.

Water is used for irrigation and the production of special foods such as algae. With the growth of global agriculture and water demand, recycling and optimized water management are essential. BIO-UV Group analyzes the needs of agricultural facilities to offer the most suitable technology, ensuring safe and quality water while respecting yields and regulations.

The reliability of our UV solutions is based on European and internationally recognized certifications, ensuring drinking water safety and regulatory compliance.

Thanks to these certifications, BIO-UV Group guarantees its customers reliable, compliant and sustainable solutions that meet the most demanding standards in the sector.