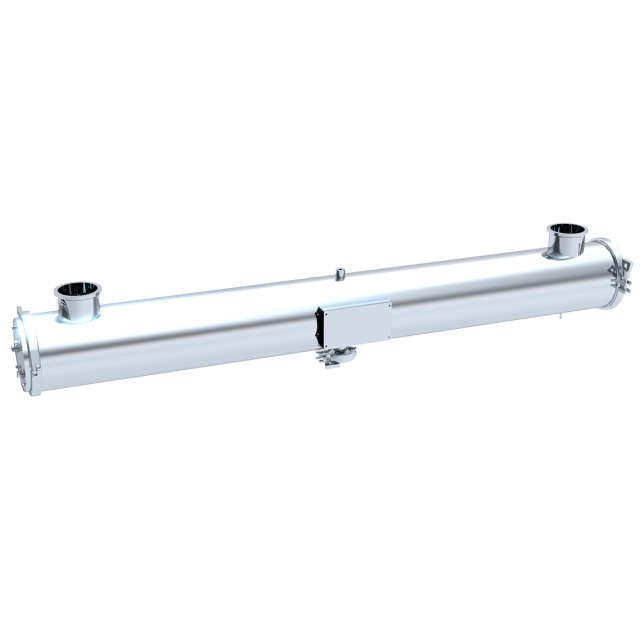

UV LPTS

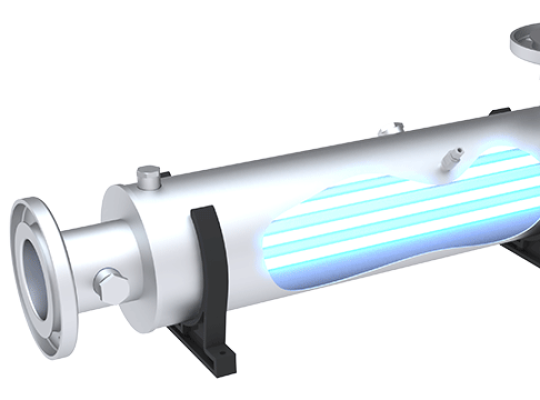

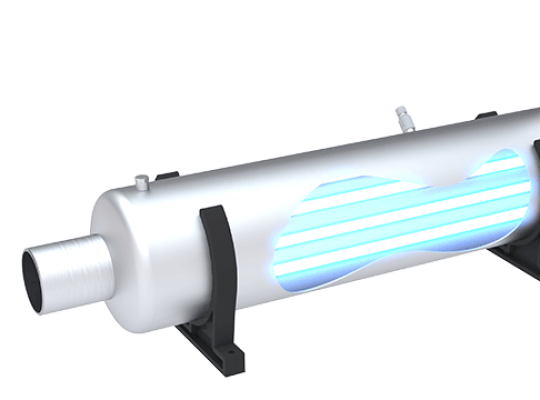

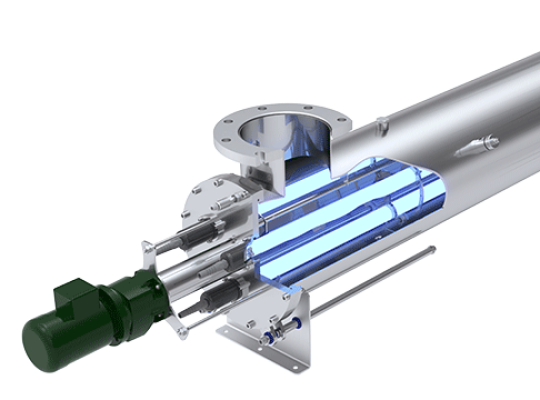

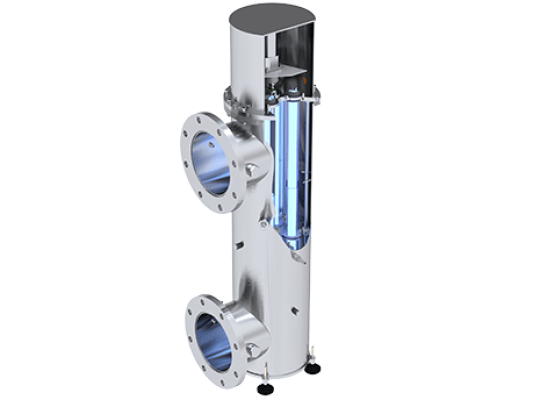

The triogen® LPTS range has been designed for deozonation, thus limiting residual ozone in treated water to achieve ultra-pure water for the electronics, semiconductor, pharmaceutical, and cosmetics industries, with a maximum flow rate of 33 m³/h. Its stainless-steel reactor and low-pressure amalgam lamps enable operation in cold, ambient, or hot water up to 60°C.

Benefits +

- Protection of sensitive systems: limits damage caused by ozone oxidation

- High ozone concentration capability: enables more effective use in oxidation processes

- Reactor material: 316L stainless steel for maximum durability

- Wetted surface finish: 0.35 μm and electropolished for optimal performance

- Easy lamp replacement: minimises system downtime

- Simple installation and operation: quick commissioning and intuitive handling

- Exceptional lamp lifetime: up to 16,000 hours

- UV sensor option: additional monitoring and control of efficiency

Technical data

| Model | Max. flow rate* | Delivered UV doses at indicated UVT / Flow rate** | UV power lamp | Connection | Reactor length |

| LPTS150-50-1 | 10 m3/h | 120 mJ/cm2 | 1 x 200 W | DN50 | 1344 mm |

| LPTS150-50-2 | 18 m3/h | 120 mJ/cm2 | 1 x 400 W | DN50 | 1344 mm |

| LPTS150-75-3 | 25 m3/h | 120 mJ/cm2 | 1 x 600 W | DN80 | 1344 mm |

| LPTS150-75-4 | 33 m3/h | 120 mJ/cm2 | 1 x 800 W | DN80 | 1344 mm |

** The performance of these devices was calculated at the lamp end-of-life and with 98% transmittance.